There are a lot of businesses that solely focus on profit… but we’re not one of them. Of course, we do need to make a profit to succeed as a business. But it’s also important to us that in everything we do, we use our business as a force for good. That means having a positive impact on people and our planet–and continuing to make the changes that will help us do more good.

Thanks to your feedback and our partners at Emerald Brand, a company specializing in revolutionary eco-friendly products, we are officially ditching inflated plastic packing material. While those little air-filled plastic bubbles might be fun to pop, they’re not exactly environmentally friendly. We’re excited to announce that your goods will now be shipped using Emerald Brand paper-based packing material made with 80 percent post-consumer fibers, which is not only recyclable, but also compostable.

According to Shao Li, a director of operations here at UncommonGoods, consumer demand for environmentally friendly initiatives are on the rise. “Emerald’s eco-friendly and cost effective solutions in the packaging category, [which use] recycled and compostable substances, provide UncommonGoods with a greener, healthier, plastic-free packaging solution,” he said.

We’ve been looking forward to this change for quite a while. On account of testing, data collecting, and final decision making, this transition has been nearly two years in the making. During this time, we monitored outgoing shipments packed with paper to ensure that our goods traveled from Brooklyn to your home in one piece. We also kept an eye on the health and safety within our own warehouse. Unlike other environmentally friendly alternatives to plastic, this packaging doesn’t compromise our warehouse team’s health through the use of dangerous blades or by putting an unhealthy amount of cardboard dust in the air.

By improving our packaging, we’re Building for the Long-Term and using our business as a Force for Good, two of our Guiding Principles. Learn more about our company values here.

Thanks to the new material, we don’t have to choose between customer satisfaction, team member well-being, or what’s best for the planet, explained Sean Cullen, who leads UncommonGoods’ Sustainability Steering Committee: “After years of searching for a suitable alternative to plastic bubble, we are excited that this shipment packaging is a win-win-win situation.”

Operations Team Lead Arnold Pittman and UncommonGoods Founder and CEO David Bolotsky using inflated plastic, our previous packing material. Photography by Christopher Lane, American Express Open Forum

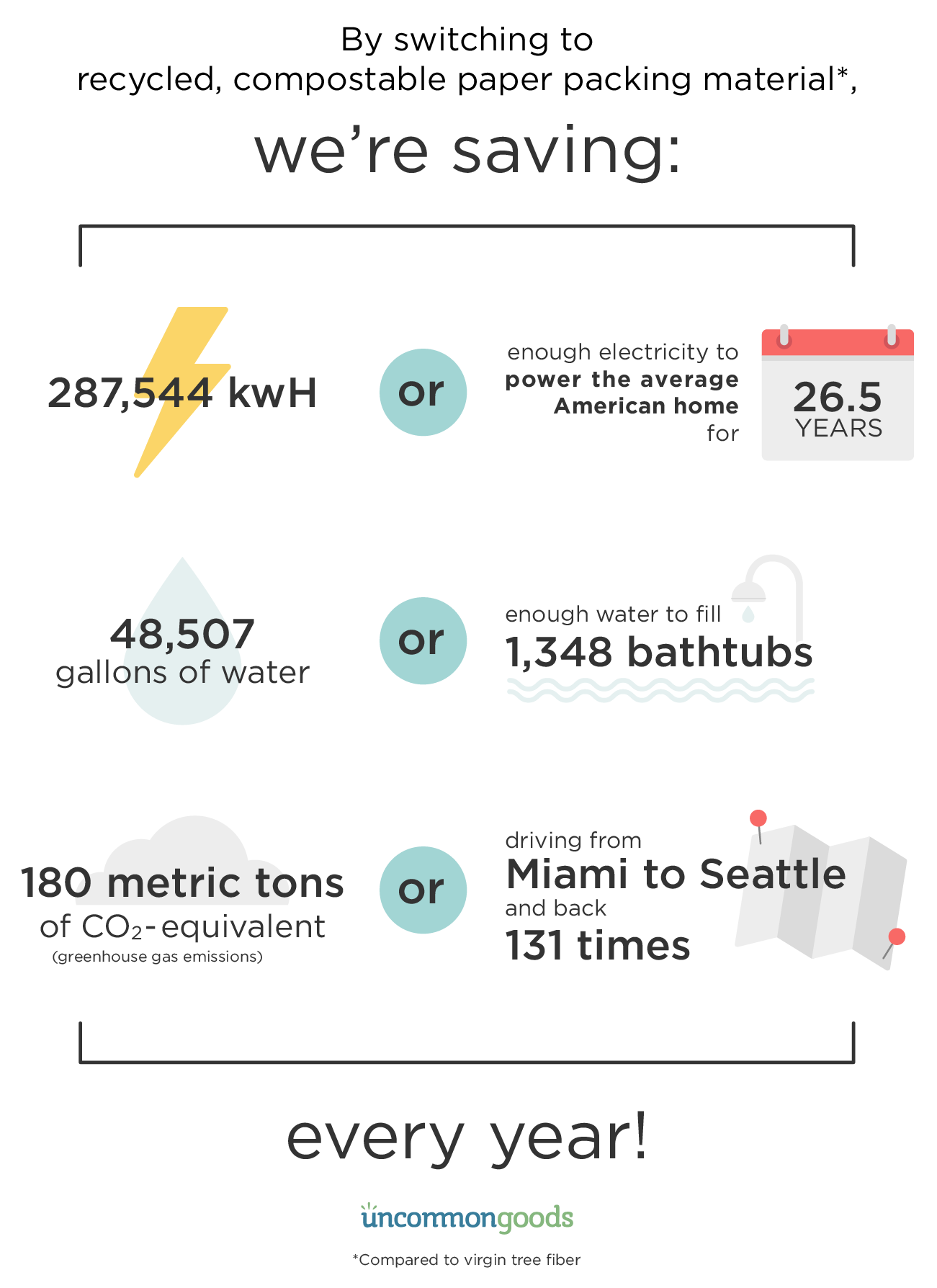

E-commerce is expected to create the strongest demand for protective packaging in the next five years. While we know there’s still work to do, we’re excited for a solution that is less taxing on the planet and easier to recycle. But don’t just take our word for it. Here’s what a year with our new packing materials will look like, according to our 2017 Annual Emerald Environmental Impact Statement:

Sources: US Energy Information Administration, US Environmental Protection Agency, USGS Water Science School, and Emerald Brand

Are you as excited about this new packaging as we are? Do you have other ideas on how our business can be a force for good? Your feedback helped us make this change and we want to hear your suggestions. Please reach out to us at feedback@uncommongoods.com.

10 Comments

We are so excited to have you as a partner!! Congratulations on ditching the plastic!! It is so nice to see that major retail companies like UncommonGoods are listening to their consumers and adopting more sustainable initiatives when it comes to packing materials.

Thank YOU, Rosanna! We are very excited to partner with Emerald Brand.

How does switching to a paper based solution save water vs. plastic? Water consumption is one of the major concerns with paper manufacturing and recycling – not one of the concerns with plastic packaging, that I am aware of.

Hi Bob. Thanks for reaching out! By switching from inflated plastic to recyclable and compostable paper, we are projected to save over 48,000 gallons of water per year. Unfortunately, plastic is believed to be even more harmful because it is less likely to be recycled and more likely to end up in our oceans. According to The Ellen MacArthur Foundation, if business doesn’t become more sustainable, by 2050 oceans are expected to contain more plastics than fish (by weight), and the entire plastics industry will consume 20% of total oil production, and 15% of the annual carbon budget.

Source: https://www.ellenmacarthurfoundation.org/news/new-plastics-economy-report-offers-blueprint-to-design-a-circular-future-for-plastics

Great. All the very best for the excellent initiative to devise ecofriendly products and to make products ecofriendly.

Thank you for the support! It means the world to us.

I want to go back to Bob’s question regarding the saving of water. I do not think you really addressed his question. You did re-iterate what your release states, but I agree with Bob in that paper manufacturing is highly consumptive of water vs most plastic processes. I would like to request a copy of the comparative LCA performed along with assumptions and the boundaries for the system. I agree that fiber-based products are likely more recyclable than plastic, but fiber products can be energy and water intensive. If you could provide me a copy of the LCA to review, I would appreciate it. Thanks.

Hi Phillip, thanks for clarifying your question. The EIS calculator used for this analysis is calculating water saved through our use of 100% recycled fiber, rather than traditional fiber product. I’m happy to discuss further with you to further break down the analysis. Can you send a message to jcoleman@uncommongoods.com?

Thank you to everyone who has commented on this post. We read every comment on our blog and every email that comes through feedback@uncommongoods.com. Upon reviewing Phillip and Bob’s comments, we realized that we originally miscommunicated the savings illustrated. The data above is meant to compare our new recycled paper packaging to traditional, non-sustainable materials. In this case, the savings are compared to virgin tree fiber (packaging that is not recycled). We’ve edited the post to better reflect the impact of the recycled paper packaging, according to our Environmental Impact Statement. Prompted by our blog comments and Phillip’s subsequent email, I am working with our team to execute a closer analysis of the water usage from our previously used inflated plastic packaging. Cutting back any negative impact we have on the environment is part of our mission and accurately communicating that to our community means a lot to us. We’ll keep everyone updated in the comments section as we learn more. As our Guiding Principles state, we are always learning! https://www.uncommongoods.com/blog//2017/uncommon-values-our-guiding-principles/

Thank you!!!!